A Complete Manufacturing Partner

A Complete Manufacturing Partner

PBZ specializes in assisting companies in their production, partnering with companies that require robust manufacturing solutions. As a leading metal manufacturing and fabrication company in Pennsylvania, we leverage our expertise and equipment to deliver comprehensive services at every process stage. Our broad experience covers a range of industries, including metal furniture, data centers, alternative energy, heavy equipment and more.

From Form To Finish

Manufactured solutions begin as concepts, and take clear vision and methodology to successfully execute.

Develop a Manufacturing Strategy

PBZ works with you from the very beginning to develop a coordinated manufacturing strategy based on open dialogue and clear communication.

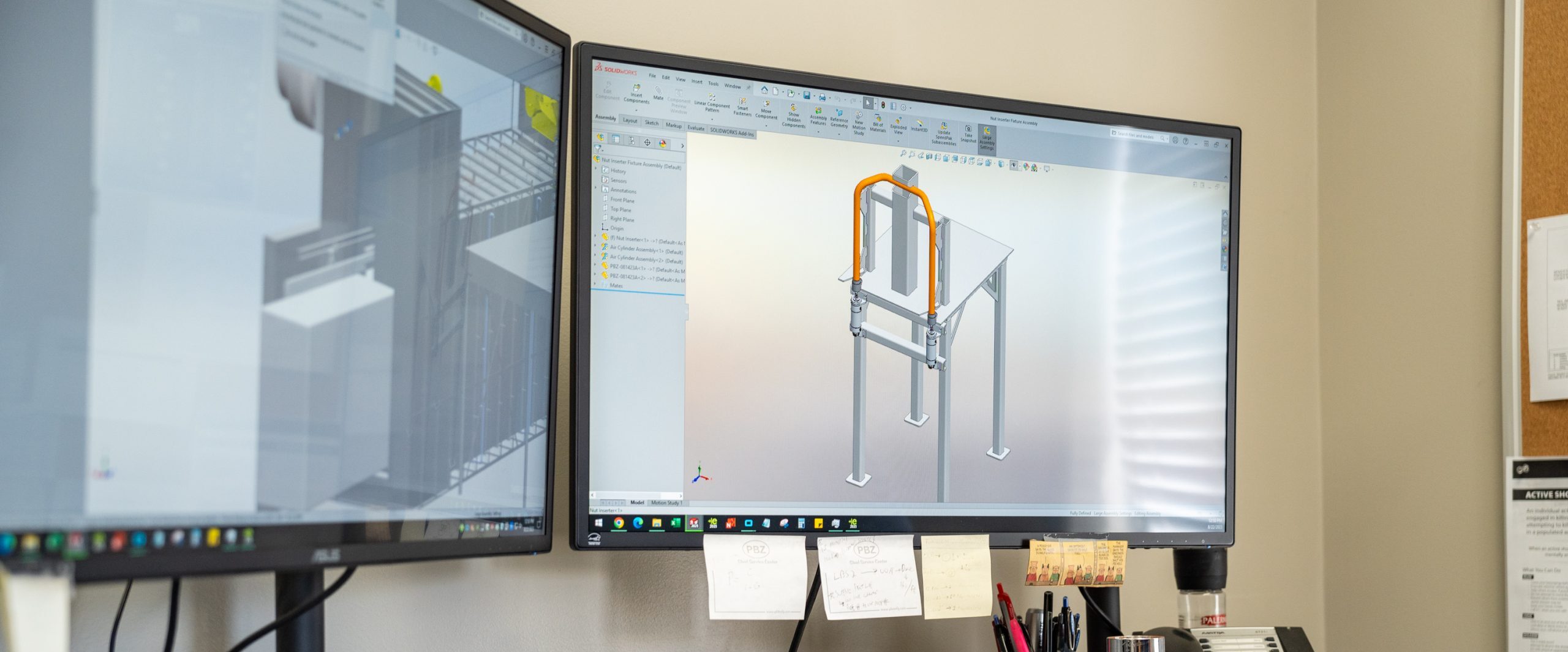

“Form” can refer to everything from your basic concept to your tried-and-true product. No matter where you are in that continuum, we’ll take your CAD drawing and prepare it for manufacturing through the use of various computer modeling technologies (both 2D and 3D) applied by our team of experienced draftsmen.

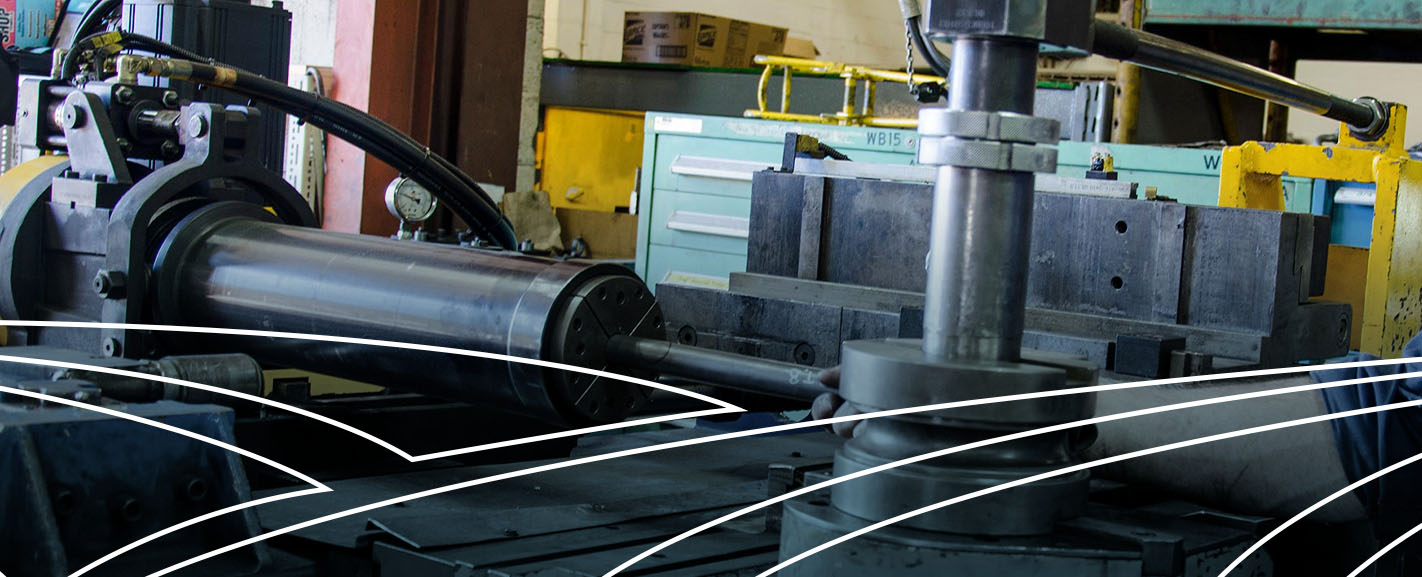

To bring your project to reality, our team uses their experience and a variety of tools, including lasers and press brakes, to get the job done right.

Read how this approach worked for a manufacturer in this customer profile.

We work diligently to ensure every project maintains a steady, productive pace from beginning to end.

Assembly & Delivery

If your project requires a finished surface, PBZ offers powder coating in Lititz through our partner Keystone Koating.

PBZ manufacturing and Keystone Koating are part of the Paul B. Zimmerman, Inc. family of companies.

Keystone Koating is an ISO certified company that offers powder coating solutions for both large and small products. Their extensive technology and knowledge within the industry has allowed them to meet the most rigorous of standards, including the AAMA 2605 standard.

Additionally, we can assemble your product and securely package it for delivery. We complete your optimized supply chain with affordable, convenient shipping practices, as we use our network of trucks to transport your product to your facility safely, or even directly to your customer or job site.

To take advantage of PBZ’s all-inclusive, turnkey manufacturing services, request a quote or other additional information by filling out our online contact form or calling us at 717-584-8767.

Resourceful Manufacturing in Lancaster County

The same resourcefulness that our founder, Paul B. Zimmerman, brought to fixing equipment for his Lancaster County neighbors starting in 1947 is in the DNA of PBZ today. We have the engineers, equipment and ingenuity to do your job right. We take the time to listen and understand your project needs before we offer a comprehensive solution.

What Our Customers Are Saying

The Latest from PBZ Manufacturing

A Complete Manufacturing Partner

A Complete Manufacturing Partner